Air Quality in Welding Shops: When Ambient Filtration is the Answer - 10-29-2025

Welding is essential to fabrication, but it creates one of the most significant workplace air quality challenges. Every weld produces smoke, gases, and fine particulates that linger in the air long after the arc stops. If not controlled, these contaminants build into a haze that exposes workers, coats equipment, and leads to safety compliance risks.

Most welding operations start with source capture using arms, booths, or hoods positioned near the arc to pull fume away. But in real-world conditions, not every particle is captured. Some smoke escapes when welders reposition, some drifts into the general shop air, and some originates in locations where hoods are impractical for primary capture. This is where ambient air filtration becomes critical as a secondary option when source capture is impossible.

Micro Air’s MXT ambient air cleaners are designed to complement source capture, removing background fume from the entire welding shop. They restore visibility, reduce worker exposure, and maintain clean air throughout the facility.

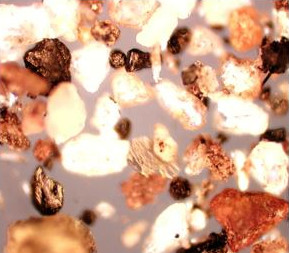

Why Welding Fume Is a Serious Air Quality Concern

Welding fumes contain fine metal particles, oxides, and gases. Depending on the materials welded, contaminants can include iron oxide, manganese, or hexavalent chromium. These particles are typically less than one micron in size, small enough to penetrate deep into the respiratory system.

Overexposure leads to health issues, from short-term irritation to long-term respiratory disease. OSHA has established strict permissible exposure limits (PELs) for welding-related contaminants. Meeting these limits requires more than partial fume control it requires a shop-wide approach that ensures both local capture and ambient cleaning.

Source Capture vs. Ambient Filtration

Source Capture involves positioning arms, hoods, or booths near the welding arc. It is the first line of defense and is highly effective when welders can position hoods correctly, removing the gases away from their breathing zone.

Ambient Filtration addresses everything that escapes source capture. Units are mounted overhead or on walls, circulating shop air continuously. They remove the haze that builds in open areas, corners, and spaces where source capture is not practical.

In welding shops, the best results come from combining both methods:

Source capture removes fume directly at the weld.

Ambient systems like Micro Air’s MXT units clean the overall air volume, eliminating residual smoke and maintaining background air quality.

When Ambient Filtration Is the Answer

Not every welding shop can rely solely on source capture. Facility managers should consider ambient filtration when:

Multiple welders work in the same space and source capture cannot cover every station simultaneously.

Welders move frequently, making hood repositioning impractical.

Large parts or assemblies prevent the use of close-proximity hoods.

Shops experience visible haze despite having some local exhaust systems.

Bridge cranes or cannot access weld area directly.

In these situations, ambient filtration ensures that the entire facility benefits from continuous air turnover and cleaning.

Micro Air’s MXT Ambient Air Cleaners

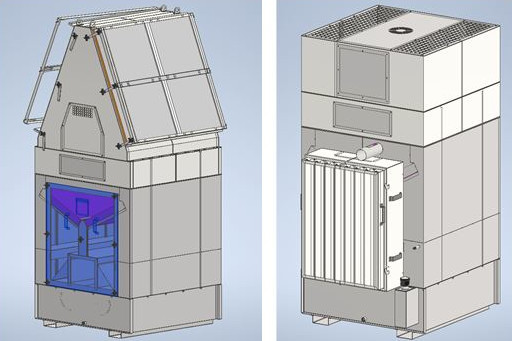

The MXT series from Micro Air is designed for heavy-duty welding environments where background fume control is essential.

How They Work

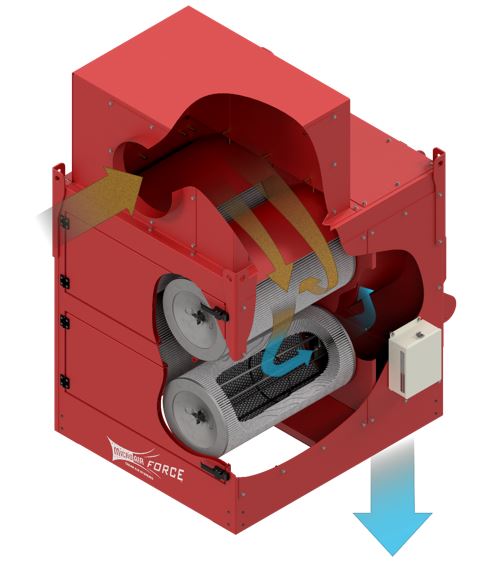

MXT units are ceiling- or wall-mounted, creating push-pull airflow patterns that continuously cycle air through filters.

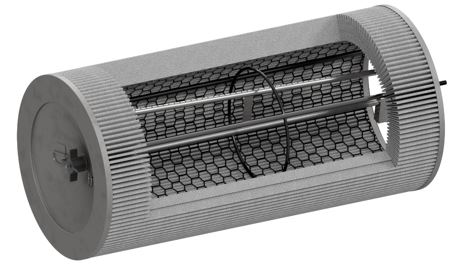

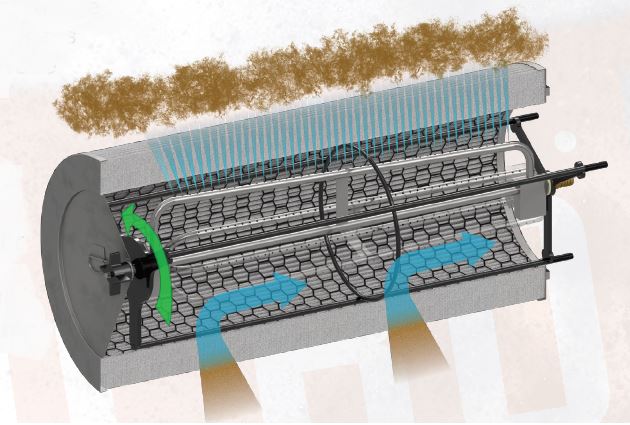

Contaminated air passes through multi-stage filtration, including high-efficiency filters for fine particulates.

Clean air is discharged back into the shop, reducing haze and restoring safe air quality.

Key Benefits

Whole-shop coverage for welding bays, fabrication areas, or open-floor layouts.

Scalable design, allowing multiple units to be combined for larger facilities.

Low maintenance, with easy filter access and long service intervals.

Compliance support, helping facilities maintain OSHA PEL limits.

Designing an Ambient Filtration System for Welding Shops

Ambient systems must be tailored to the size and activity level of the shop. Considerations include:

Air changes per hour (ACH) required to maintain clean background air.

Ceiling height and floor area, which determine the number and placement of MXT units.

Type and intensity of welding, which influences filter media selection.

Integration with source capture to create a layered approach.

Micro Air engineers work with facility managers to calculate airflow requirements, design layouts, and configure MXT units for maximum coverage and efficiency.

Maintenance and Monitoring

Even with robust equipment, maintenance is essential for performance. For MXT units, best practices include:

Monitoring filter differential pressure to track loading.

Replacing filters when efficiency declines.

Inspecting units regularly to ensure airflow patterns remain balanced.

Cleaner Welding Shops with Ambient Filtration

For welding shops, air quality is both a safety and compliance priority. While source capture remains the first defense, it cannot solve every challenge. Micro Air’s MXT ambient air cleaners provide the final layer of protection, ensuring that haze, background smoke, and residual fumes are eliminated across the facility.

With scalable designs, easy maintenance, and proven filtration, MXT units allow facility managers to maintain safe air, protect workers, and simplify compliance with OSHA standards.

Ready to Improve Air Quality in Your Welding Shop?

Micro Air designs complete air filtration systems for welding environments, including source capture solutions and MXT ambient cleaners. Share your shop size, welding processes, and compliance needs, and our team will configure the right solution.

Breathe easy. With Micro Air, welding shops run cleaner, safer, and more productive.

Read more →